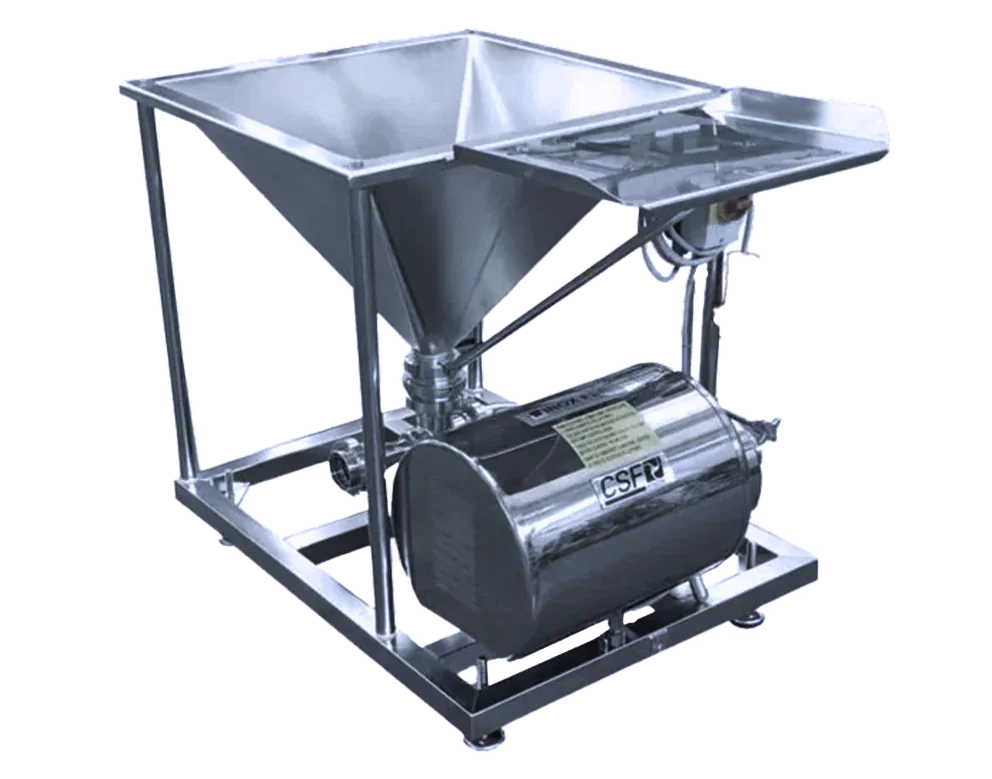

discover our dissolving system

Sugar dissolving system – DR System – has been designed to dissolve sugar and work with low viscosity blends, as well. The system is a compact unit that is equipped with a removable bag holder by the hopper. Sugar is one of the most important dry ingredient for many products such as soft drinks and juices and it requires a tailored dissolving system according to the customer’s needs.

Our DR system for sugar can be combined with pasteurisation of the sugar solution, storage tanks, other treatments and options if needed.