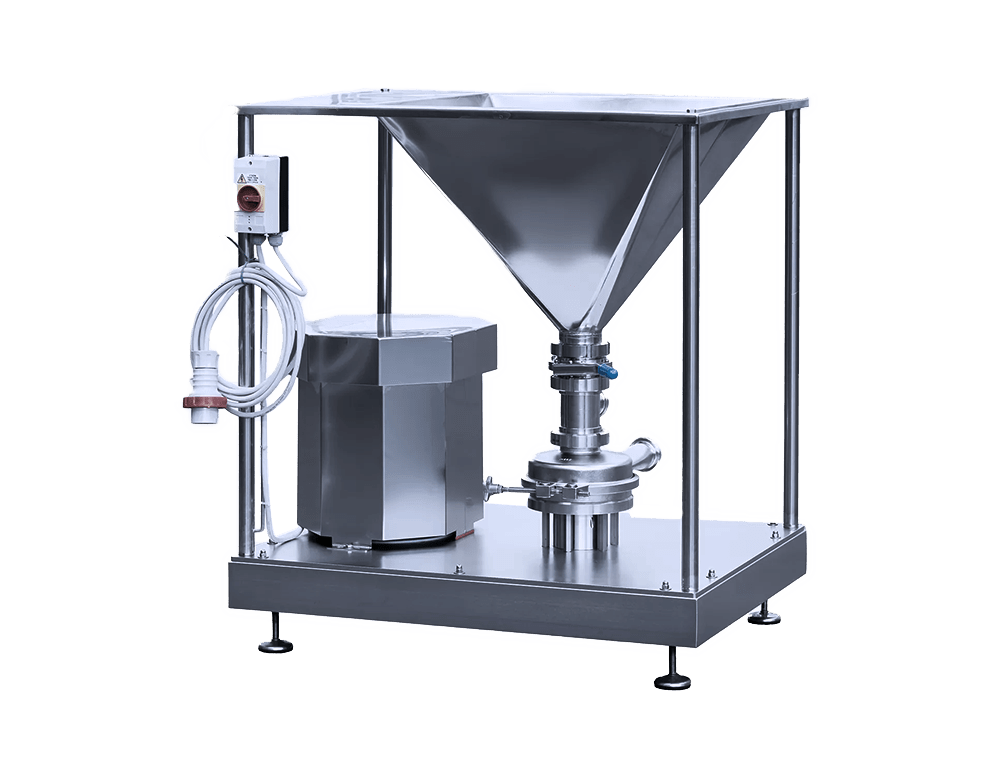

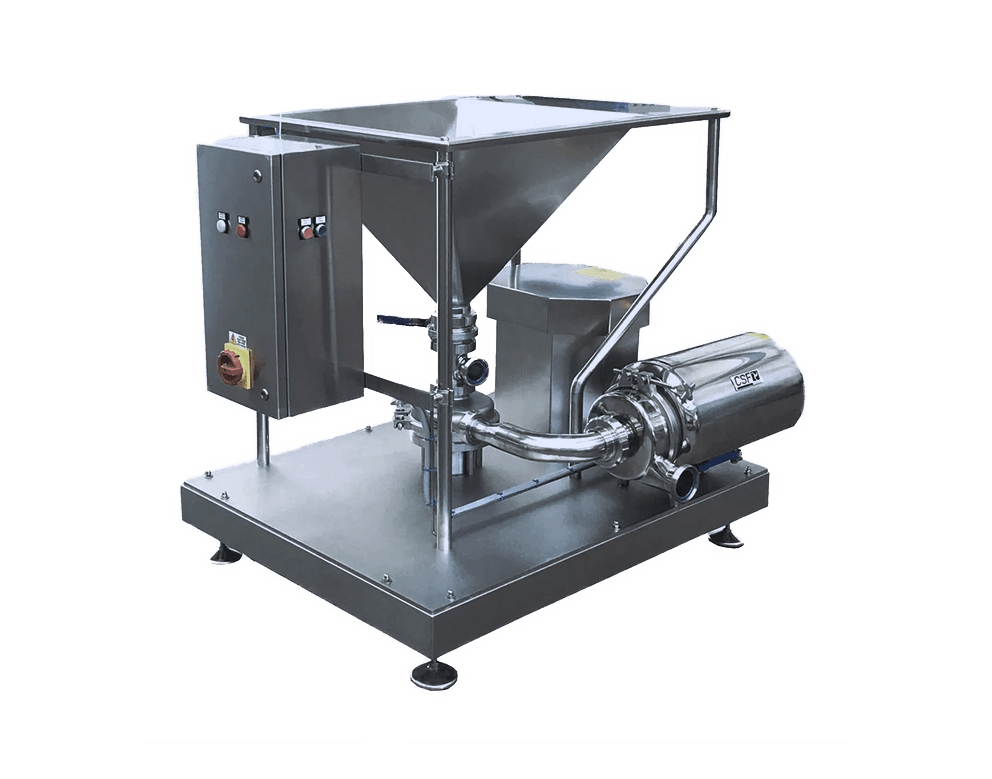

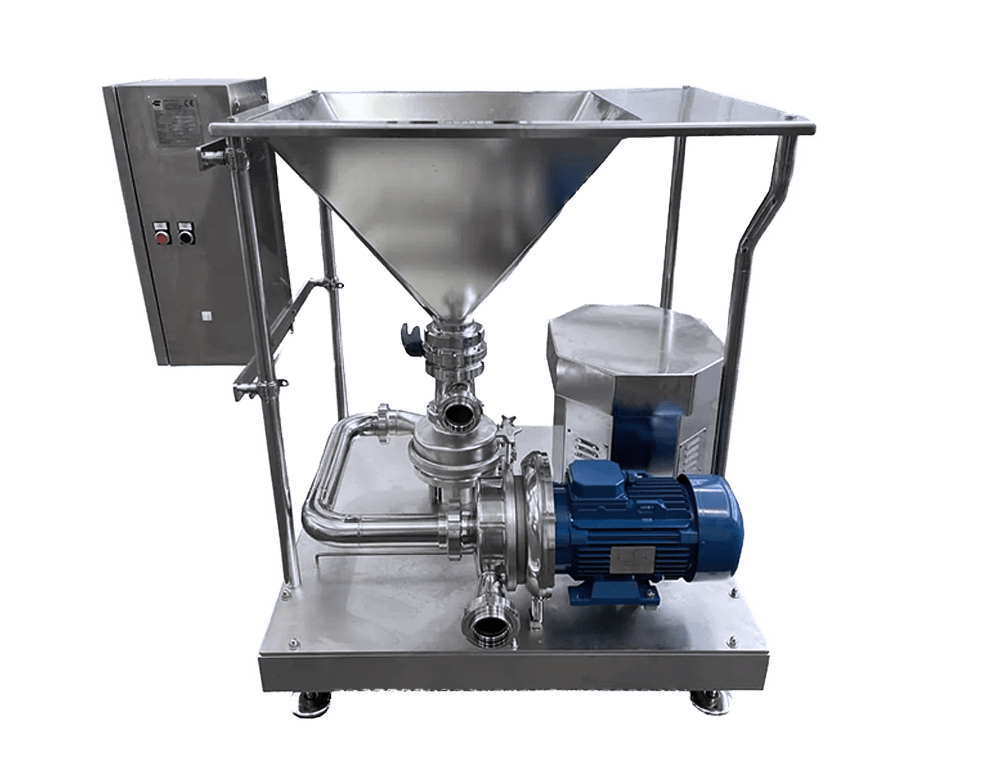

discover our powder mixer

The TMV powder mixer is designed to handle large quantities of product and for mixing highly viscous product such as pectins, starches, thickeners, proteins and caseinates. It is also aimed at syrup preparations, milk powder reconstitution and consistent brine preparations. All ingredients, but especially the heavier ones, are micronised and dispersed so finely that the viscosity of the final product obtained is reduced as much as possible.

With the TMV powder dissolver, mixing times are reduced to a minimum. Dispersion/solubilisation with the dissolver is instantaneous, even sugar and salt are crushed and solubilised immediately. No lumps are formed and the problem of those harder granular ingredients that do not dissolve and settle on the filters of any subsequent processing steps is eliminated.