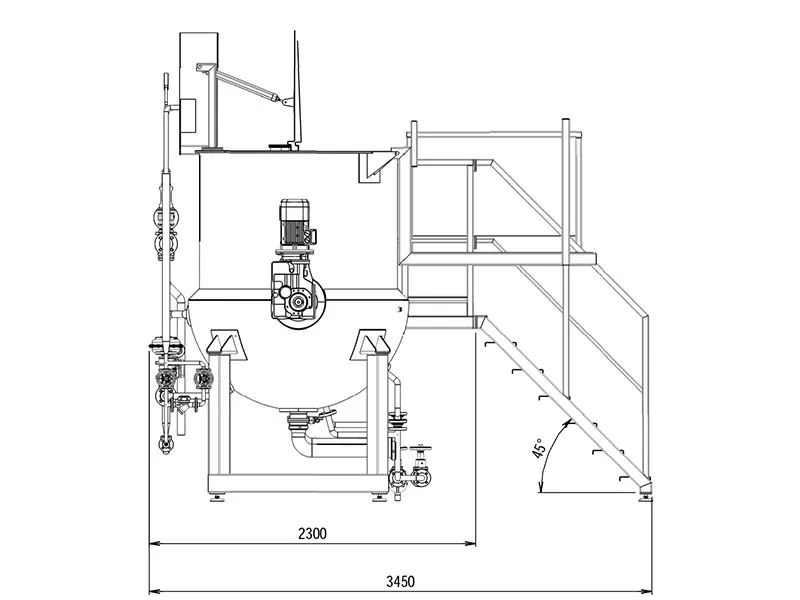

what is a jacketed kettle

The Jacketed Kettle is one of the most widespread machines used for cooking mixing at atmosferic pressure of different type of products such as tomato puree, sauces, ragout and dressings. The shape of the vessel is generally vertical while cooking takes place by steam. The machine is equipped with scraping paddles in order to avoid burns of the product on the bottom.

This Inox-Fer cooking kettle is equipped with a heating and insulation capacity in order to heat the product within the desired period of time.