Background

In the world of food processing, mixing is one of the stages in most applications. From simple dissolution of powders to the homogenisation of ingredients, the process has a substantial impact on the finished product. This is where the choice of machinery designed to the specific needs of the manufacturer becomes strategic.

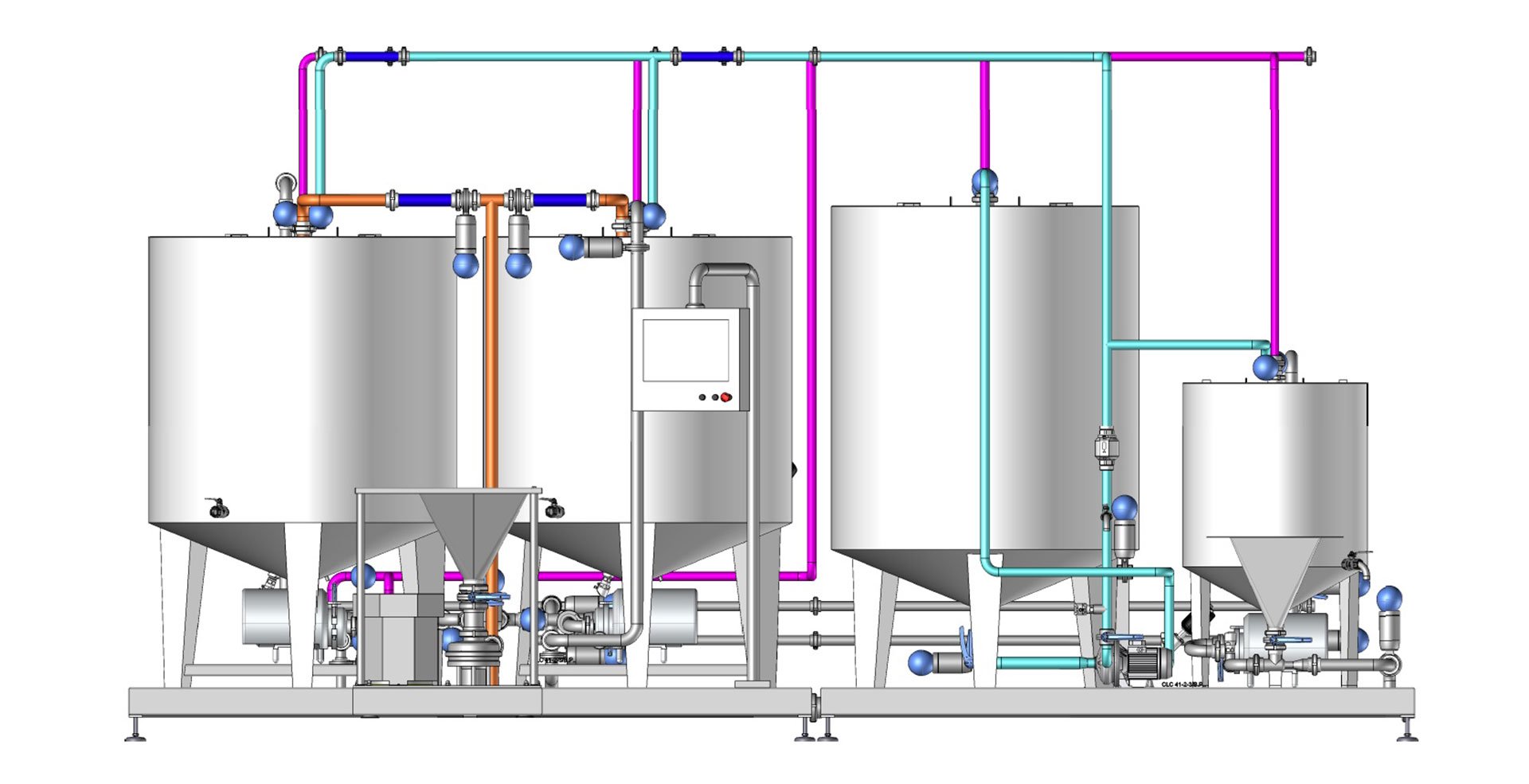

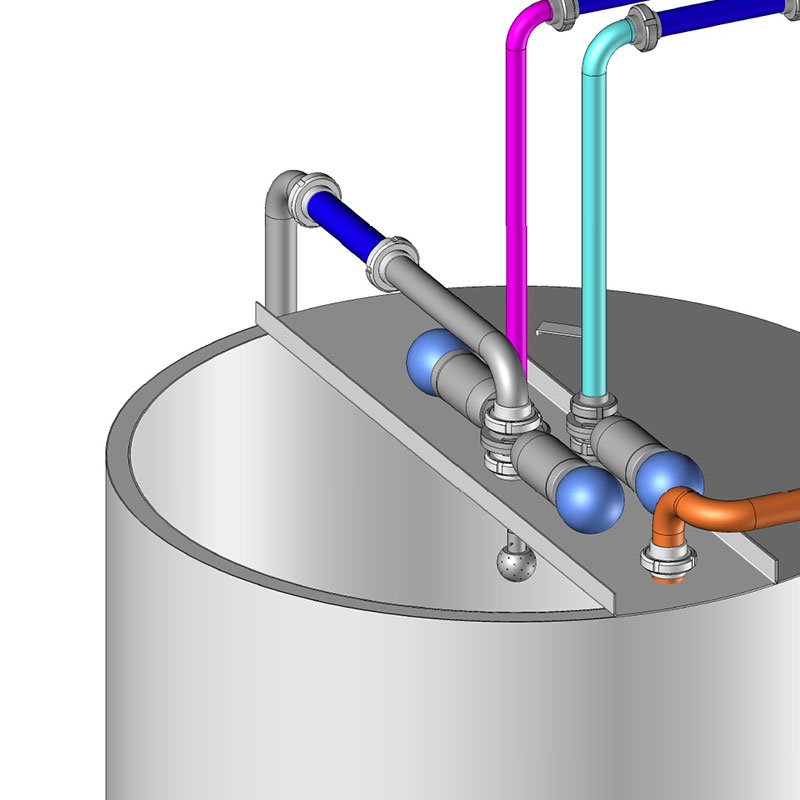

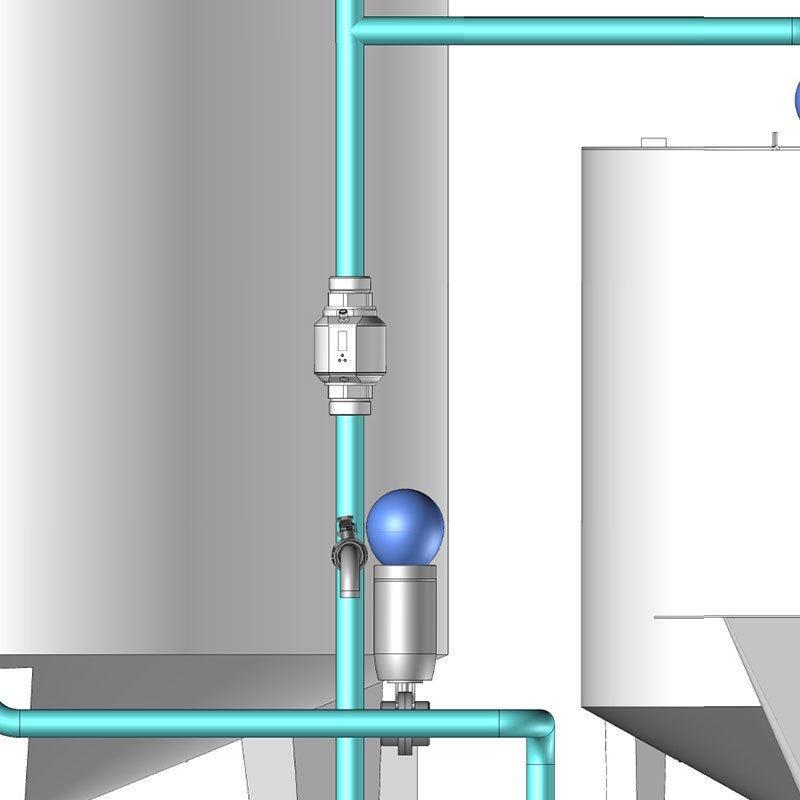

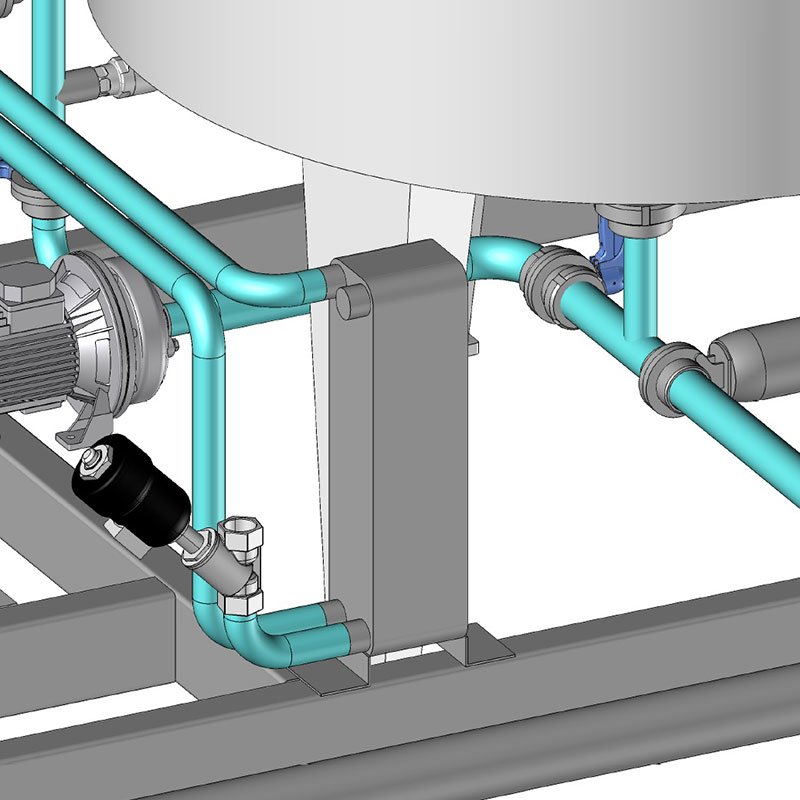

At Inox-Fer, we specialise in the design and manufacture of highly customised mixing systems.