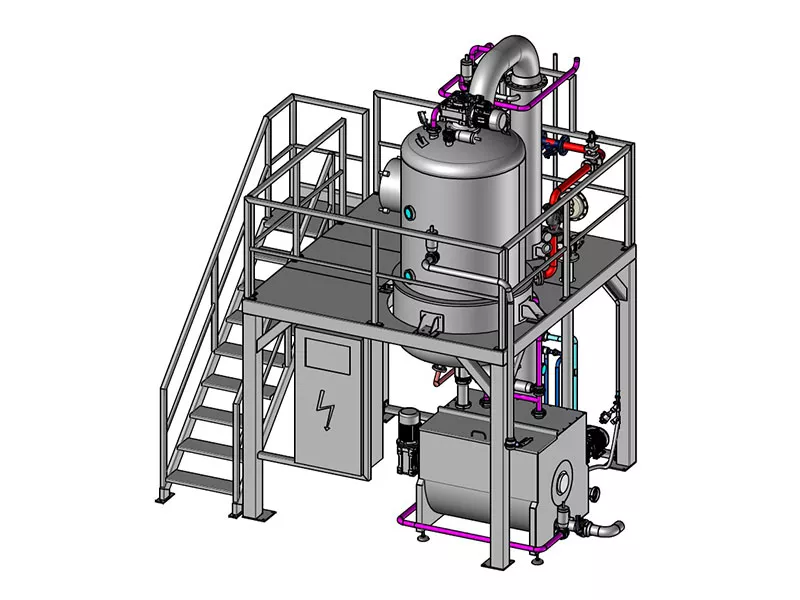

Discover our Industrial vacuum kettle

The Industrial vacuum kettle is the optimal solution for the production of sauces, jams, marmalades and condiments.

Vacuum processing makes it possible to concentrate, cook and dehydrate the product at low temperatures and in less time, ensuring a final product of excellent quality that preserves the organoleptic characteristics compared to using a traditional cooker.