Jam production is a process where tradition meets innovation. In recent years, advances in food processing technology have made it possible to achieve high-quality products in reduced processing times, while ensuring maximum food safety and consistent standards.

Among the most advanced solutions available on the market, the ProCut Easy industrial cooker stands out for its versatility, efficiency, and customization capabilities.

In this in-depth article, we explain how ProCut Easy supports professional berry jam production, the benefits it offers to food laboratories and industrial manufacturers, and how it optimizes every stage of the production process.

The Role of Technology in Modern Jam Production

Producing jams and preserves requires precise control over several critical variables, including:

- Temperature

- Cooking time

- Cutting intensity

- Mixing performance

- Evaporation

- Preservation of the fruit’s natural color

In professional environments, these phases must be repeatable, automated, and scalable, without compromising the organoleptic quality of the final product.

This is exactly where ProCut Easy makes the difference.

ProCut Easy: The Industrial Cooker Combining Creativity and Performance

ProCut Easy is designed to meet the needs of food manufacturing companies looking to innovate their production lines while maintaining the flexibility typical of artisan food laboratories.

It is a professional industrial cooker for purees and jams, capable of integrating:

- Vacuum cooking to preserve color and nutrients

- Homogeneous mixing, even with high-density ingredients

- Controlled cutting, allowing both chunky jam and smooth puree textures

- Smart automation, reducing errors and increasing productivity

- Integrated cooling, ideal for delicate recipes

Thanks to these features, companies can develop new recipes, test formulations, and achieve consistent product quality.

How We Produce Berry Jam in Our Test Kitchen

In our culinary R&D center, we tested several recipes using the full potential of ProCut Easy.The goal was to obtain a rich, smooth, and aromatic berry jam, while reducing processing time and maximizing fruit yield.

Simple Ingredients, Professional Results

For our berry jam recipe, we recommend starting with selected raw materials:

- Fresh berries (blueberries, raspberries, blackberries, red currants)

- Sugar

- Lemon juice

- Natural spices or flavorings according to customer requirements

Here, technology truly makes the difference, enhancing ingredient quality without excessive thermal stress.

The Production Process with ProCut Easy: Step by Step

The industrial cooker was used with the Cooling option activated, ensuring full control over every process variable.

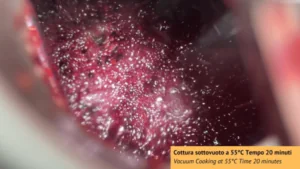

PHASE 1 – Preparation and Gentle Cooking

✔ Preserves fruit shape and color

✔ Maintains authentic aromatic profile

✔ Keeps visible fruit pieces

PHASE 2 – Cutting and Texture Refinement

✔ Achieves a uniform and smooth puree

✔ Controlled cutting prevents oxidation and aroma loss

✔ Entire process takes place in a single machine

Characteristics of the Final Jam

The finished product features:

- Bright, natural color

- Full and intense flavor

- Creamy yet structured texture

- Improved shelf stability

This jam is suitable both for direct consumption and as an ingredient for:

- Tarts and baked goods

- Sweet leavened products

- Yogurt and desserts

- Artisan fillings

Why ProCut Easy Is Ideal for Jam Manufacturers

Beyond product quality, ProCut Easy offers strategic advantages for food producers.

Efficiency and Reduced Processing Time

The complete production cycle takes less than one hour, with no need for transfers or additional machines.

Total Process Control

Temperatures, cooking times, texture, and cutting speed can be precisely set and repeated.

Production Versatility

Ideal not only for jams, but also for:

- Sauces

- Creams

- Compotes

- Hummus

- Vegetable and fruit purees

- Pastry fillings

Suitable for Small and Large Batches

The ProCut Easy line allows processing of different batch sizes while maintaining consistent quality.

Reduced Waste and Consistent Quality

Vacuum cooking and automated control minimize evaporation and maximize raw material yield.

Innovation in Food Processing: Where Technology Meets Creativity

Adopting equipment like ProCut Easy is a strategic investment for companies aiming to:

- Increase production capacity

- Improve quality standards

- Develop customized recipes

- Reduce costs and waste

- Gain a competitive market advantage

In a constantly evolving food industry, flexible and high-performance equipment enables manufacturers to respond quickly to customer demands and market trends.

ProCut Easy: The Ideal Solution for Modern and Sustainable Production

Our experience producing berry jam with ProCut Easy confirms the system’s effectiveness:

fast, intuitive, versatile, and capable of delivering excellent results in every batch.

Whether you operate an artisan workshop or an industrial facility, this cooker is a key ally in elevating your production quality.

Want to know if ProCut Easy is the right solution for your company?

Contact us for a personalized technical consultation, or explore all features in the complete industrial cooker technical datasheet.

FAQ – Frequently Asked Questions About Jam Production with ProCut Easy

ProCut Easy ensures precise control of temperature, cooking time, and final texture. Vacuum cooking and homogeneous mixing deliver natural color, intense flavor, and uniform texture, while reducing waste and processing time.

Yes. A gentle initial cooking phase preserves whole or semi-whole fruit pieces. Activating the cutting phase later allows you to obtain a smooth and velvety puree. Texture is fully customizable.

ProCut Easy is suitable for sweet creams, compotes, sauces, fruit and vegetable purees, pastry fillings, hummus, and many other food processing applications.

The full process takes approximately 45 minutes, including vacuum cooking, mixing, and cutting.

Vacuum cooking preserves color, flavor, and nutritional properties by operating at lower temperatures, preventing oxidation and maintaining a fresh aromatic profile.

The cooker is designed for quick and easy cleaning. Hygienic internal surfaces and automated controls simplify daily operation and maintenance.

Absolutely. ProCut Easy allows full recipe customization by adjusting temperature, time, cutting level, and mixing intensity.

Ideal for food startups, ready-to-eat producers, and industrial food manufacturers working with sauces, jams, fillings, and purees.

Yes. Vacuum cooking minimizes evaporation and thermal damage, improving yield and raw material preservation.

Yes. It can operate as a standalone unit or be seamlessly integrated into complete food processing and packaging lines.

Saremo felici di rispondere ad ogni domanda