Sommario

- 1 🔍1. Initial Analysis: The Foundation of Every Custom Food Processing Equipment

- 2 Co-Design: Collaborative Approach with the Client

- 3 🧩3. 3D Design and Simulations

- 4 🏗️4. In-House Stainless Steel Production

- 5 🧪5. Testing and Final Validation

- 6 🚚6. Installation, Commissioning, and Training

- 7 🎯The Result: Custom Food Processing Equipment, Backed by 45 Years of Experience

- 8 Planning your next custom food processing equipment?

- 9 FAQ – Custom Food Processing Equipment

In the food processing industry, every company has unique production needs, space constraints, and goals. That’s why custom food processing equipment is not simply an adaptation of standard solutions—it is designed from scratch to perfectly integrate into the client’s production line.

In 2026, INOX-FER, based in Borzano di Albinea (Reggio Emilia), celebrates 45 years of experience in designing and manufacturing stainless steel equipment for the food industry. A milestone reflecting technical expertise, continuous innovation, and reliability.

In this article, we explore how custom food processing plant is developed, following the INOX-FER method—from initial request to final commissioning.

🔍1. Initial Analysis: The Foundation of Every Custom Food Processing Equipment

Creating custom plant always starts with a detailed technical analysis, essential for defining the real project requirements.

Studying Existing Production Processes

During this phase, the technical team examines:

- current production processes

- workflow patterns

- available space

- operational challenges

Defining Performance Objectives

The analysis helps define:

- required production capacity

- food safety standards

- operational continuity and equipment reliability

Co-Design: Collaborative Approach with the Client

A cornerstone of the INOX-FER method is co-design, a collaborative approach that ensures custom equipment truly meets operational needs.

Designing in Synergy with the Client

This phase includes

- preliminary layout of the equipment

- alternative technological solutions

- stainless steel materials and finishes

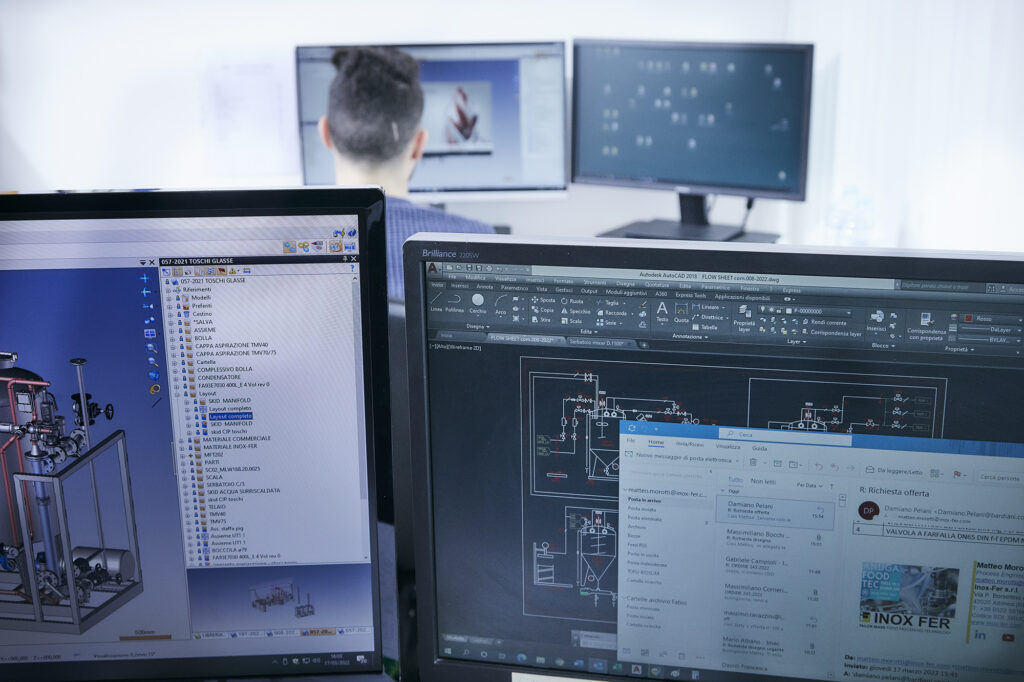

🧩3. 3D Design and Simulations

From preliminary planning, the project moves to 3D modeling and technical simulations, crucial for optimizing custom equipment before production.

Simulations allow:

- structural verification

- space optimization

- compatibility with existing lines

The digital model prevents unexpected issues during installation and commissioning.

🏗️4. In-House Stainless Steel Production

All custom equipment is manufactured in-house at the INOX-FER facility in Borzano di Albinea.

Processes include:

- cutting, bending, and rolling

- certified welding

- surface finishing and treatments

- assembly and pre-assembly

In-house production ensures full control, traceability, consistent quality, and compliance with food industry standards.

🧪5. Testing and Final Validation

Before delivery, every piece of equipment undergoes a rigorous internal testing phase.

Tests include:

- safety checks

- performance testing

- process parameter validation

- simulation of real operating conditions

Only after passing all tests is the equipment ready for installation.

🚚6. Installation, Commissioning, and Training

The project concludes with:

- installation at the client’s production site

- integration with existing lines

- commissioning and final adjustments

- personnel training

- delivery of technical documentation

This phase ensures that custom plant operates efficiently, safely, and immediately.

Only after passing all tests is the equipment ready for installation.

🎯The Result: Custom Food Processing Equipment, Backed by 45 Years of Experience

The INOX-FER method—based on analysis, co-design, 3D simulation, and validation—delivers custom food processing equipment that is:

- highly personalized

- safe and compliant with regulations

- efficient and durable

- optimized to reduce consumption and maintenance

An approach that, after 45 years, continues to evolve alongside food industry companies.

Planning your next custom food processing equipment?

Rely on INOX-FER’s 45 years of expertise: we support food companies in designing and manufacturing highly customized stainless steel solutions.

FAQ – Custom Food Processing Equipment

If you experience bottlenecks, waste, cleaning difficulties, or need higher automation, a dedicated system can improve efficiency and quality—without necessarily increasing costs. Request a free evaluation of your production process.

Costs vary depending on production requirements, materials, and automation levels. We can provide a detailed, obligation-free quote after a short technical consultation.

Yes, on-site inspections are an integral part of our method. Our team can visit your facility to analyze workflows and needs. Contact us to book a priority inspection.

Our design lines are already active: we can start new projects quickly. Book a consultation now to secure available slots for 2026.

Yes. We offer technical assistance, scheduled maintenance, and dedicated interventions. Our clients are never left alone. Contact us for information on our support plans.

Absolutely. We can analyze your existing system and propose technical and economic improvements, including estimated savings. Book a free comparative analysis.

The first step is simple: contact us. We will arrange a technical meeting, gather your requirements, and prepare a personalized proposal.

You can send us a message via our website, call, or email us. We will respond promptly. Click “Request Consultation” to speak directly with an INOX-FER technician.