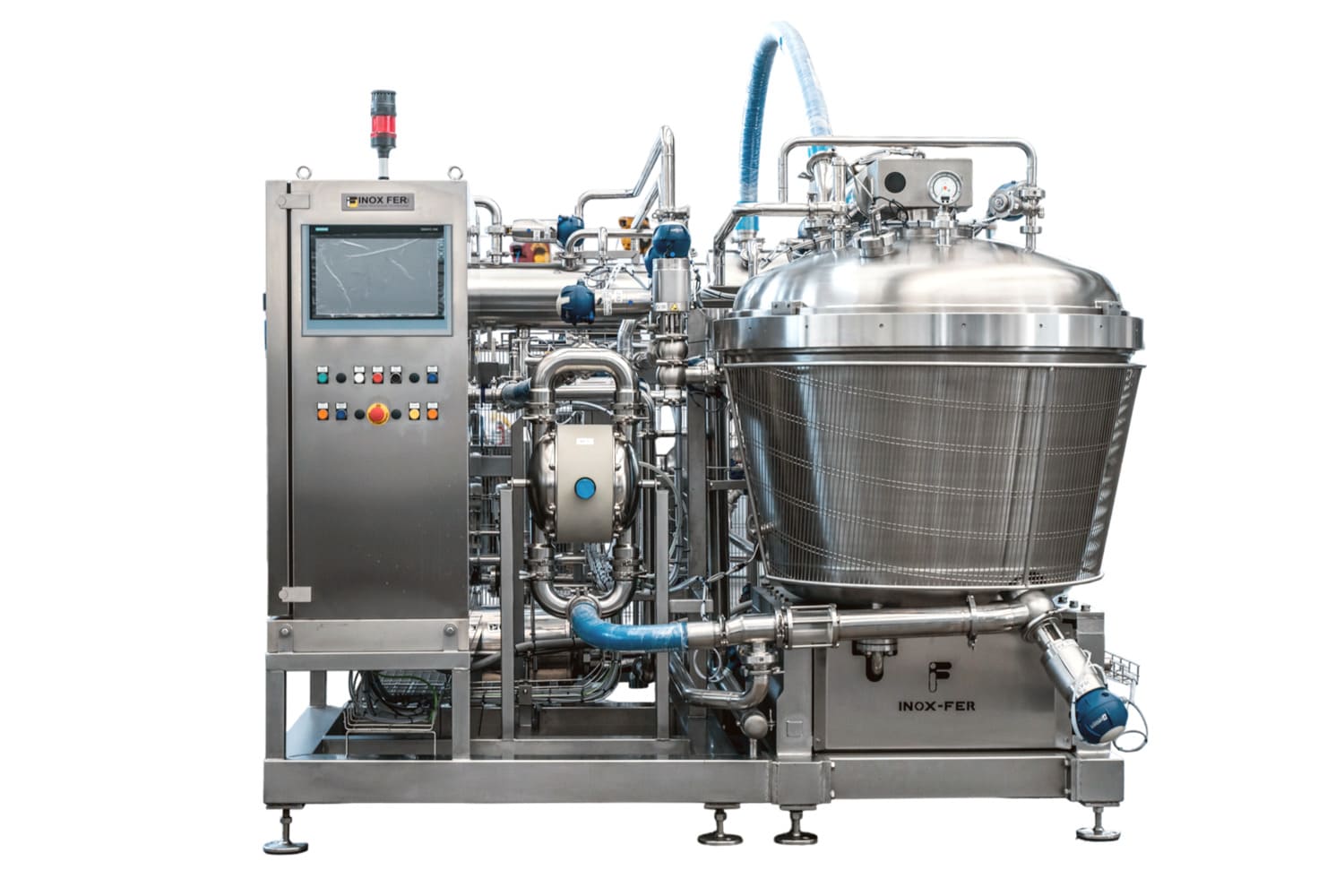

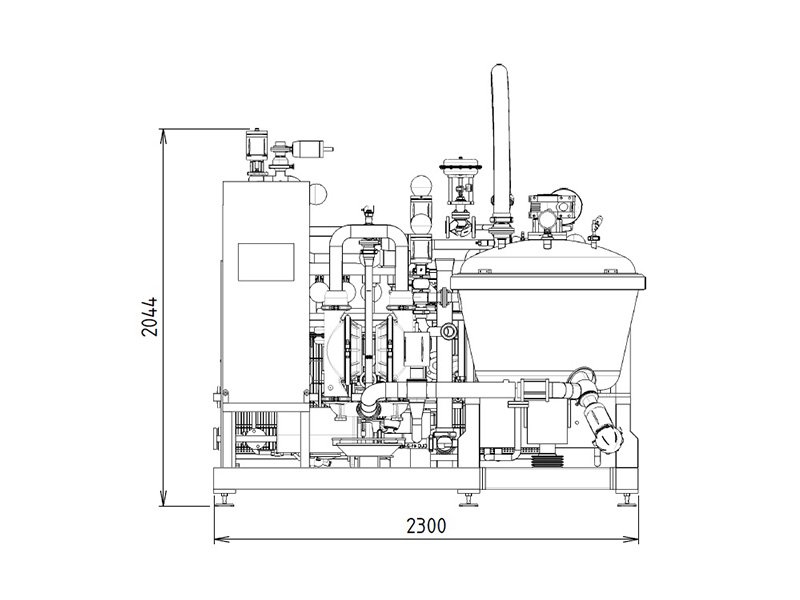

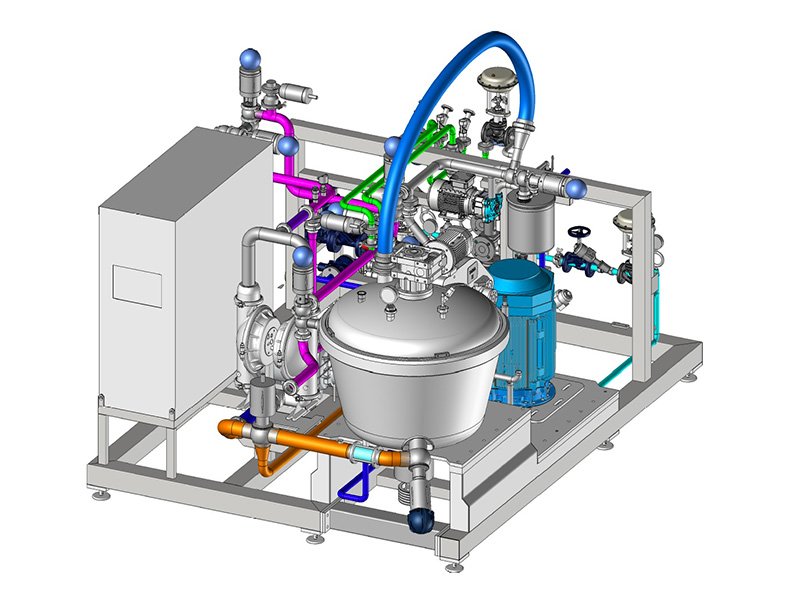

Our ProCut industrial cooker

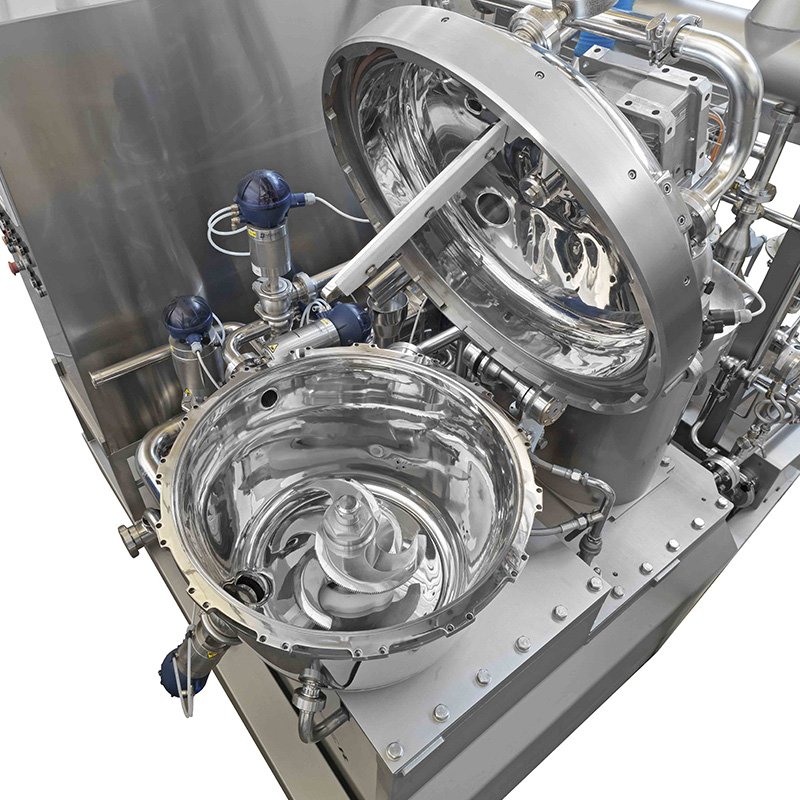

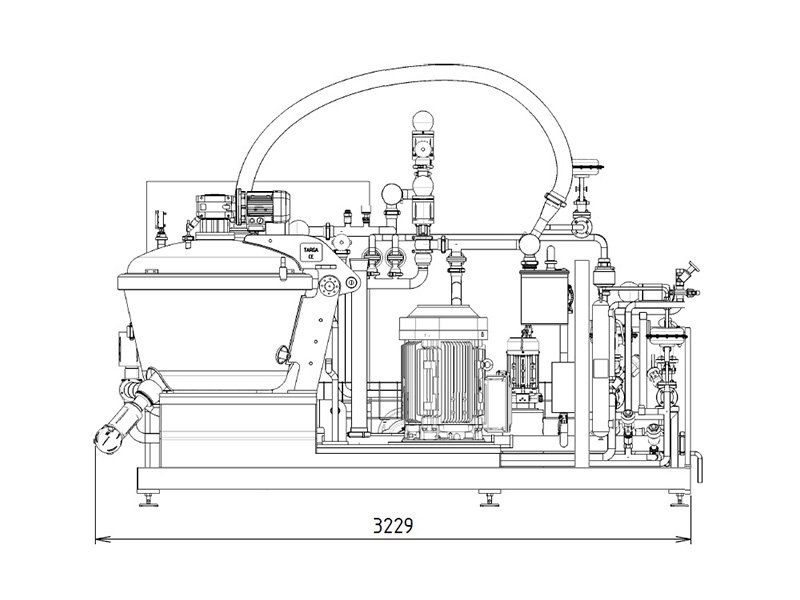

The Procut is an Industrial cooking kettle designed as a single piece of equipment that produces a finished product.

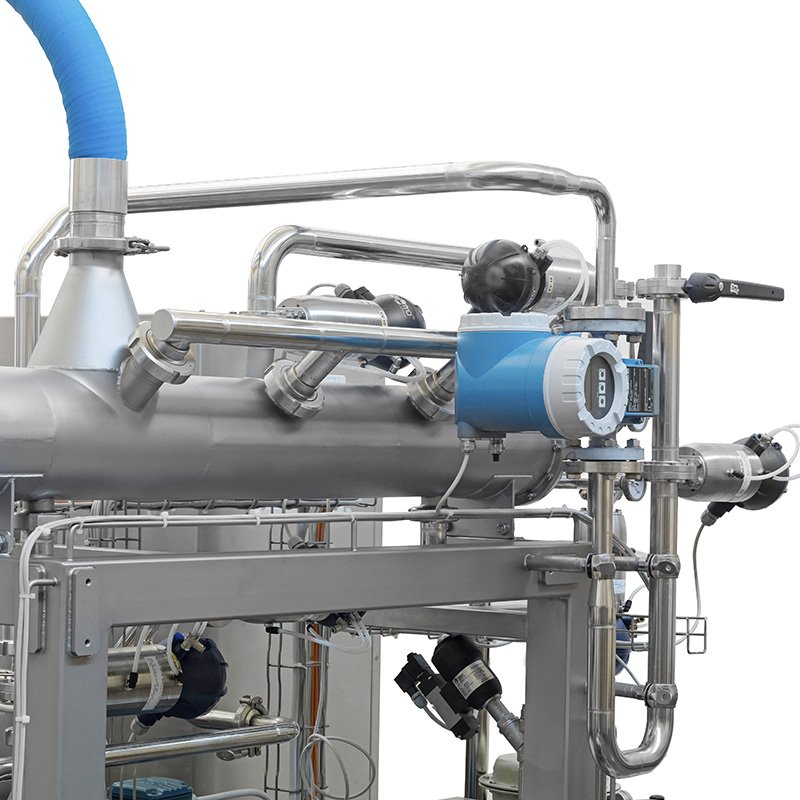

It’s a complete solution for food processing featuring all the capabilities.

The ProCut industrial cooking kettle has been designed to obtain a finished product starting directly from the raw material using a single machine and a single work cycle.

The Procut Industrial Cooker is the ideal machine for medium and large companies.