Sommario

We are thrilled to announce our participation in Anuga FoodTec 2024, the most important exhibition in the food technology panorama. In this article, we will guide you through the solutions we will present at the event.

Anuga FoodTec: an international and innovative fair

Anuga FoodTec presents itself as the only exhibition in the world that competently covers all aspects of food and beverage production, ranging from process technology to filling and packaging technology, food safety, packaging, digitalisation and ‘intralogistics. A relevant addition for the 2024 edition is the exhibition area dedicated to environmental and energy technology.

When and where will Anuga FoodTec be

We will meet in Cologne from 19 to 22 March 2024, in an international context where you can explore the latest solutions for the productive success of your company.

Inox-fer Solutions in the Foreground

TMV75 – Integrated Corn Gluten & Potassium Hydroxide Dissolver

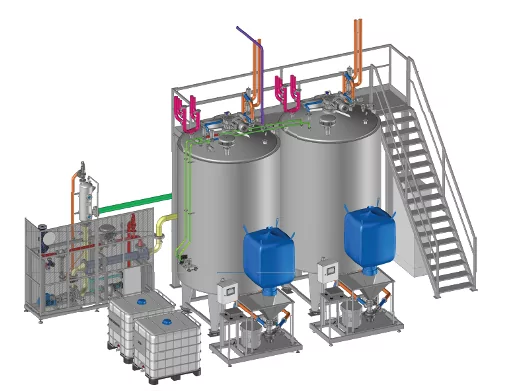

Attendees will be able to see our advanced TMV75 dissolver for high viscosity products up close. Integrated into a mixing plant of our own design, equipped with two 10,000 litter tanks, this unique system allows the mixing of corn gluten, potassium hydroxide and enzymes in osmotic water for the production of fertilizers.

Our system, designed by the Inox-fer technical team, stands out for its precision in the loading of liquid and solid ingredients, thanks to the use of load cells for both the tanks and the dissolvers. Equipped with a tube chest heat exchanger powered by superheated water, it guarantees gradual and delicate heating of the product, exceeding the efficiency of traditional steam.

To facilitate access to the 10,000 litter tanks, which have a considerable height, we have included a ladder. Paddle stirrers centered on the bottom prevent product deposits and stratifications.

pH control and its correction are facilitated by a pump with milk of lime or soda, maintaining the desired value for 4 hours.

The micro ingredient scale, positioned next to the hopper, ensures precision in weighing enzymes, even in minimal quantities (around 5 kg), crucial for the recipe. Two piston dosing pumps simplify the loading of acid and basic product via suction tube. With this system, we offer integrated, high-precision solutions for the most advanced needs of your production.

Procut Easy 60

This custom-made industrial cooker is the excellence for small and medium-sized businesses specializing in the production of sauces, creams, pesto and jams. The innovative Procut Easy 60, the result of advanced engineering, stands out for its unique ability to respect the quality of raw materials by exploiting highly professional instrumentation.

Carefully designed to create excellent finished products, the Procut Easy 60 is a multifunctional industrial cooker. Its features include fundamental operations such as precise cutting, homogeneous mixing, sous vide cooking to preserve aromas and texture, and concentration to enhance flavors.

Transparency to test us

We offer the possibility of testing the system in our factory; Furthermore, Procut Easy 60 can be rented to verify its inclusion in your company’s production.

We like to test our systems with new recipes: watch the video or read the article dedicated to preparing hummus with Procut Easy 60.

Mixing system for Government Liquid Production TMV40 C9

Our mixing system was specifically designed and built for the production of preserving liquid for gherkins, with a focus on the American market. Equipped with a 900 litter tank and the TMV40 dissolution system, it stands out for the excellence of its electrical components by Allen Bradley, a widely recognized brand compliant with UL regulations adopted by US companies.

The design includes a dished top, ensuring maximum internal hygiene, with an inspection hatch strategically positioned to facilitate mixing verification. To meet the different cleaning standards of the American market, the corner frame created demonstrates the commitment to meeting the different standards of hygiene and practicality. A mixing system that combines precision, safety and ease of maintenance to excel in the production of preserving liquid for gherkins.

Participate with Inox-Fer – Request your ticket

Join us in this exchange and networking experience at Anuga FoodTec 2024. Discover the latest technologies, meet industry experts and seize growth opportunities for your company. Our team will be happy to share the tailored approach for small and medium-sized businesses.

Inox-fer gives you free entry to the fair – Write an email with the subject “Tickets” to marketing@inox-fer.com. Don’t wait, they are in limited quantities!